Explore the capabilities of long travel igus® e-chains®, expertly designed to meet the demands of extensive machinery movement. Accompanied by Treotham's complimentary design service, these e-chains® are perfect for applications requiring long-distance, gliding movement. Ideal for industries seeking reliable and efficient cable management solutions for extended travel distances.

Features and Benefits

- Customised Design Service by Treotham: Benefit from Treotham's free design service, ensuring your long travel application is precisely calculated for optimal performance.

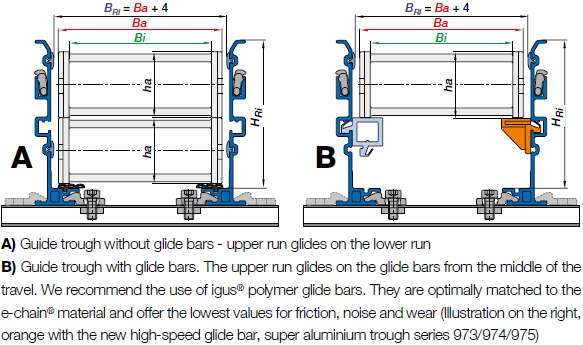

- Efficient Gliding Mechanism: The upper run of the e-chain® smoothly glides over the lower run and glide bars, minimising friction and enhancing movement efficiency.

- Optimal Guide Trough System: These guide troughs ensure lateral guidance and continuous, low-friction operation in long travel applications.

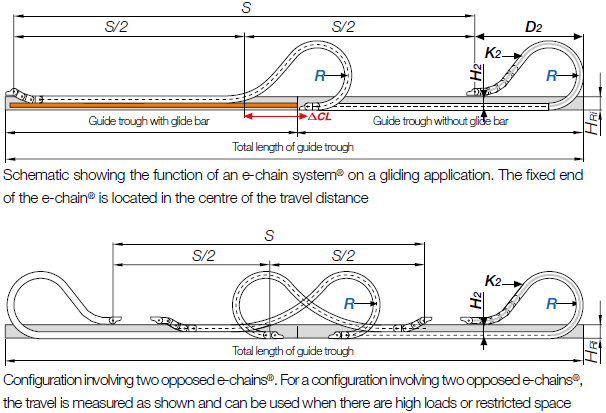

- Calculated Chain Length for Balance: Using the formula Lk = s/2 + K2, the e-chain® length ensures balanced distribution for stable and efficient operation.

- Specialised Glide Bars: We recommend using polymer glide bars from igus®, designed to offer the lowest values in friction, noise, and wear and perfectly matched to the e-chain® material.

- Durable and Noise-Reduced Design: The igus® e-chains® are built for durability and are designed to operate with minimal noise, making them suitable for various industrial settings.

- Customisable Installation: Depending on the selected e-chain® and technical requirements, the mounting point can be adjusted, including a lowered moving end for certain units.

- Precision in Long Travel Applications: Ideal for any industry where machinery must travel long distances without sacrificing precision or efficiency.

We recommend that Treotham calculate every long travel application (gliding) for you. Treotham offers a free design service.

For long travels, the upper run of the igus® e-chains® rests on the lower run. The upper run of the chain glides partly on the lower run and partly on a glide bar. The diagram below shows this. For lateral guidance, a guide trough is necessary. If the stationary mounting bracket and the fixed end of the cables and hoses can be placed in the centre, the e-chain® length is calculated as follows: Lk = s/2 + K2

Depending on the technical data and the selected e-chain®, the mounting point of the moving end of the e-chain® must be lowered on some units (lowered moving end).

Guide troughs allow igus® e-chain® and e-tubes to continue smooth, low-friction operation in long travel applications. Principle sketches are shown below. The height of the trough must be at least twice that of the e-chain® height. The sides must provide a chamfered opening. The trough inner width is the same as the e-chain® outer width, plus 4mm. Along the side of the trough, where the upper run cannot glide on the lower run, glide bars must be installed. We recommend the use of polymer glide bars from igus®. They are optimally matched to the e-chain® material and offer the lowest values for friction, noise and wear.