Elevate your operational dynamics with the impeccable torque density and precision of WITTENSTEIN alpha's servo gearboxes, brought to you by Treotham.

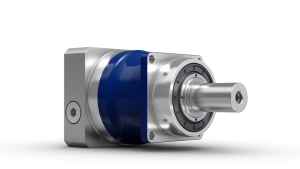

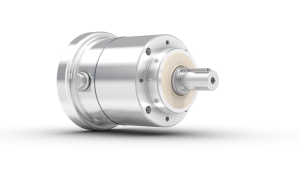

Engineered for maximum precision and dynamic performance, our low-backlash planetary and right-angle gearboxes are a testament to innovation and precision.

With an offering that spans across various applications and performance ranges, and aided by our intuitive sizing tools, we can ensure your drive train, inclusive of our elite servo gearboxes, is optimally designed for peerless performance and reliability.

Features and Benefits

- Exceptional Torque Density: Delivering high-performance motion with optimal torque in a compact design.

- Precision-Engineered: Low-backlash planetary and right-angle gearboxes designed for supreme accuracy and reliability in operation.

- Versatile Application Suitability: Catering to any application and performance range with meticulously crafted servo gearboxes.

- Optimisation with Sizing Tools: Achieve the optimal design for a complete drive train with our advanced sizing tools.

- Unparalleled Performance: Ensuring maximum precision and dynamics to meet the rigorous demands of varied industrial applications.

Gearbox Types Available

| Gearbox Type | Description | Ideal Applications |

|---|---|---|

| Servo Gearboxes | High-performance planetary gearboxes offering low backlash, high torsional stiffness, and excellent precision. | Robotics, CNC machines, automation lines |

| Right-Angle Gearboxes | Compact gearboxes with angular power transmission; ideal for space-restricted environments without compromising torque. | Conveyors, packaging equipment, tight spaces |

| Hygienic Gearboxes | Corrosion-resistant with smooth surfaces for easy cleaning; designed for clean-room and wash-down settings. | Food processing, pharmaceuticals, medical equipment |

| Servo Actuators + Accessories for Servo Gearboxes | Pre-assembled systems with mounting accessories for easy integration into motion control setups. | Customised drive trains, modular automation systems |

Planetary vs Right-Angle Gearboxes

| Criteria | Planetary Gearboxes | Right-Angle Gearboxes |

|---|---|---|

| Efficiency | High | Slightly reduced due to bevel stage |

| Backlash | Extremely low (ideal for high precision) | Low (application dependent) |

| Space Requirements | Larger axial footprint | Space-saving, ideal for tight installations |

| Torque Transmission | Optimised for inline load transfer | Effective with angular redirection |

| Applications | CNC, robotics, automation | Conveyors, packaging, hygienic equipment |