Navigate through a spectrum of precision and power with Treotham’s extensive range of linear units, featuring products from industry-leading brands such as Thomson, Neff, and Tollo.

From the most compact and discrete to the largest and most robust units, our lineup ensures adaptability to varied industrial needs.

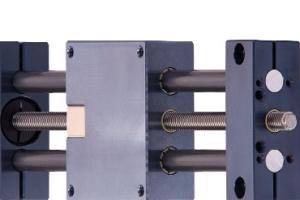

Offering a diverse array of ball screw and belt-driven units, utilising many guide technologies, our linear units are meticulously designed to perform impeccably in harsh environments, high-speed scenarios, and high-precision systems alike.

Features and Benefits

- Wide Product Range: From compact to robust, our linear units cater to a myriad of application needs and size prerequisites.

- Diverse Mechanisms: Offering both ball screw and belt-driven units to ensure optimal functionality in varied operational contexts.

- Enduring Performance: Crafted to excel in harsh environments, ensuring durability and reliability even in the most demanding conditions.

- High-Speed and Precision: Engineered to perform with impeccable accuracy and at elevated speeds, ensuring operational efficiency.

- Reputable Brands: Featuring products from renowned brands like Thomson, Neff, and Tollo, assuring quality and performance.

Comparing Ball Screw and Belt-Driven Linear Unit Types

| Feature | Ball Screw Linear Units | Belt-Driven Linear Units |

|---|---|---|

| Precision | Exceptional (µm-level repeatability) | Moderate to high |

| Speed | Slower, controlled motion | Faster movement possible |

| Load Capacity | High (ideal for heavier payloads) | Moderate |

| Maintenance | Requires lubrication | Lower maintenance |

| Application | High-precision, short-stroke tasks | Long travel, high-speed automation |

Selecting the Right Linear Unit

Consider the following when choosing your linear motion system:

- Required stroke length and accuracy

- Load weight and duty cycle

- Desired speed and acceleration profile

- Mounting and control system compatibility

- Environmental conditions (dust, moisture, temperature)