News

-

Posted: August 24, 2023Categories: Flexible CablesRead More

Pluggable glass fibre connection made easy from Treotham.

Digitalisation in industry is increasing rapidly. Data volumes are also rising quickly accordingly. A future-proof communication infrastructure in factories with glass fibre cables is therefore essential.

-

Posted: August 23, 2023Categories: IgubalRead More

Record-low costs and sustainability: our new slewing ring bearing

igus is adding a ready-to-install low-cost variant made from regranulated high-performance plastics to its iglidur PRT series

It is affordable, compact, lightweight and ready to install with a mouse click: igus has added a minimalist low-cost variant to the portfolio of its iglidur PRT series of slewing ring bearings. The PRT-05-15-PC not only reduces costs, but also protects the environment. The new slewing ring bearing consists of 97% regranulated high-performance plastics.

-

Posted: August 22, 2023Categories: EuchnerRead More

The multi-talented MGB2 Modular can now do even more

The MGB2 Modular secures safety doors and fences on machines and installations during hazardous machine movements. A modular design is the secret behind the system’s adaptability to specific requirements.

-

Posted: August 20, 2023Categories: Artificial Intelligence (AI)Read More

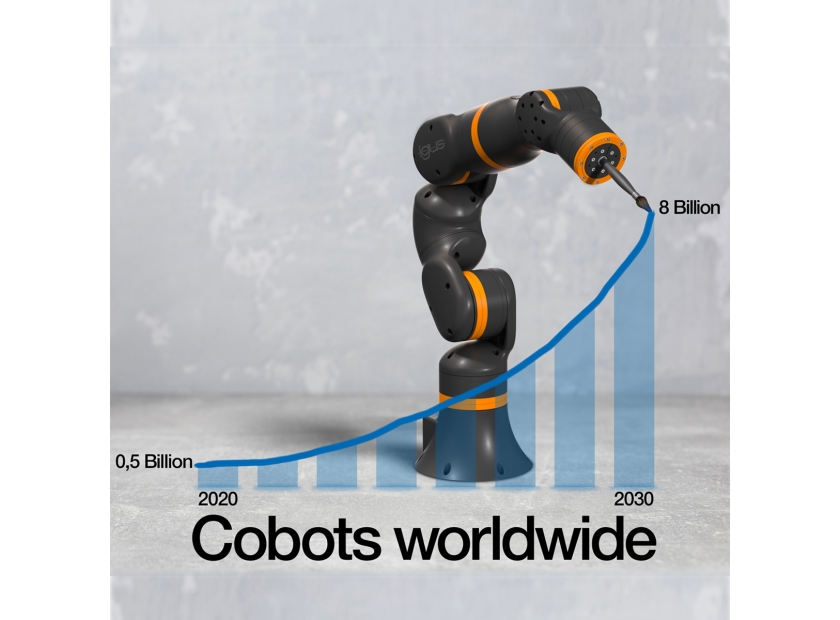

Artificial intelligence and automation: SMEs must not miss the boat

Low Cost Automation from igus promises obstacle-free entry into the robot era.

Accountants, journalists and even computer scientists are all amazed at how rapidly automation is developing, including with artificial intelligence. Industry representatives are, too. They are drawing new ideas for smart factories. Many traditional SMEs, however, are in danger of falling behind. Low Cost Automation can provide immediate assistance and help them avoid missing the boat.

-

Posted: August 20, 2023Categories: igusRead More

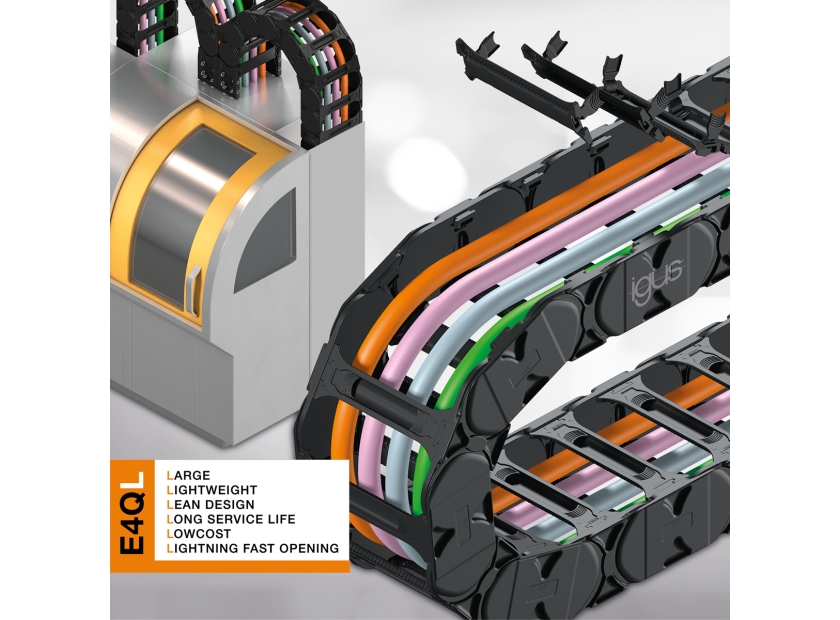

Great strength, little weight: new low-cost igus energy chain for unsupported applications

The E4Q.64L's bionic design means that it costs up to 20% less than its big brother, the E4Q

New addition to the igus energy chain portfolio: the E4Q, a globally proven e-chain for applications with large unsupported lengths and high fill weight, now has a new variant: the "L". Users for whom the E4Q is too large can now save costs of up to 20% with the E4Q.64L. They will still benefit from the advantages of its big brother, such as quick, tool-free opening.

-

Posted: June 01, 2023Categories: igusRead More

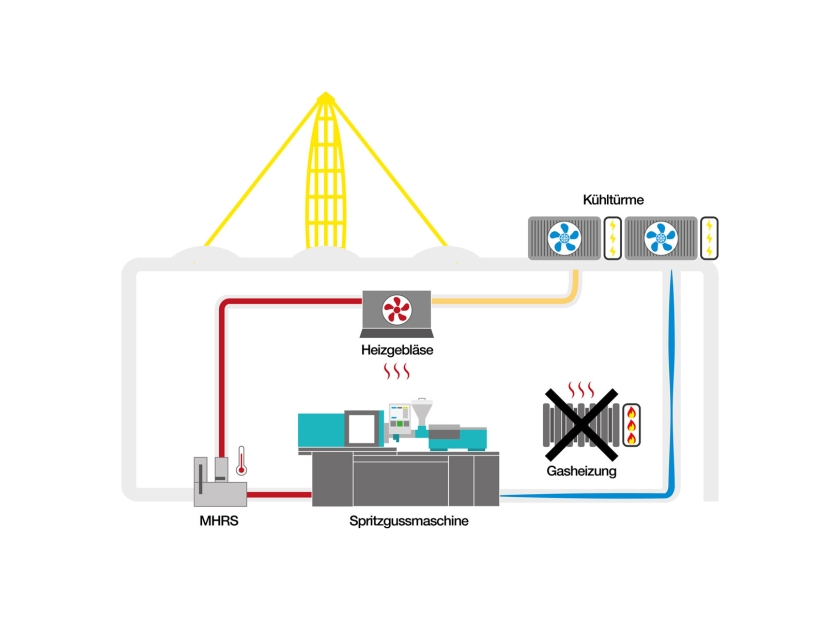

Machine Heat Recovery System from igus heats industrial factories using waste coolant water – a concept free for all to us

Engineers from igus are now using a simple technology for heat recovery. It heats industrial factories with the waste coolant water from machines, saving on gas costs and CO2 emissions. igus is making the technology available online, with all the details available to other industrial companies. If all injection moulders worldwide were to use the technology, over 14 million tons of CO2 and over seven billion cubic metres of gas could be saved.

-

Read More

Heavy loads are no problem for the new igutex TX3 fibre wound material

igus launches a new lubrication-free material, the endurance runner which is ideal for heavy-duty applications.

In applications with loads of more than 80Mpa, plain bearings made of thermoplastic materials can be pushing their limits.

-

Posted: May 16, 2023Categories: HygienicRead More

Clean, safe, lubrication-free: igus presents the hygienic design linear guide

A self-draining design, iglidur high-performance plastic and stainless steel ensure an exceptionally hygienic linear guide

Cleaning with chemicals is a daily occurrence for machines in the food processing industry. Even the smallest blind spot can collect moisture and can lead to contamination within the machine. More and more operators are therefore designing parts with an emphasis on Hygienic Design. igus is a member of the EHEDG and has developed the first linear guide system, based on the Hygienic Design guidelines. Using FDA-compliant materials such as the high-performance polymer iglidur A160, high-alloy stainless steel and a washable interior of the carriage ensures the hygienic design is adhered to.

-

Posted: May 15, 2023Read More

WITTENSTEIN’s miniaturized Galaxie® gearbox is a newly developed, high precision gearbox with axial power transmission. Compared to strain wave gearboxes with the same footprint, it convinces with much better torsional rigidity, significantly higher torque density, double the emergency stop torque and an almost 50% larger hollow shaft diameter, depending on the size.

-

Posted: May 15, 2023Read More

Maximum safety in battery production: first certified energy chain for the dry cleanroom

Test passed with the best possible result: E6.29 from igus receives innovative dry cleanroom certificate from Fraunhofer IPA for ISO Class 4

Whenever the highest hygiene standards are required, igus scores high with lubrication-free and abrasion-resistant plastic components for movement. In particular, battery production for tomorrow's mobility requires special environmental conditions, which are achieved through the combination of dry rooms and cleanrooms.