wenglor

-

Posted: December 02, 2024Categories: WenglorRead More

Time-of-flight sensors with wintec from the wenglor sensoric group stand for reliability and efficiency in object detection. Thanks to DS technology, they effortlessly detect objects on all surfaces, regardless of whether they are dark, glossy or transparent.

-

Posted: December 02, 2024Categories: WenglorRead More

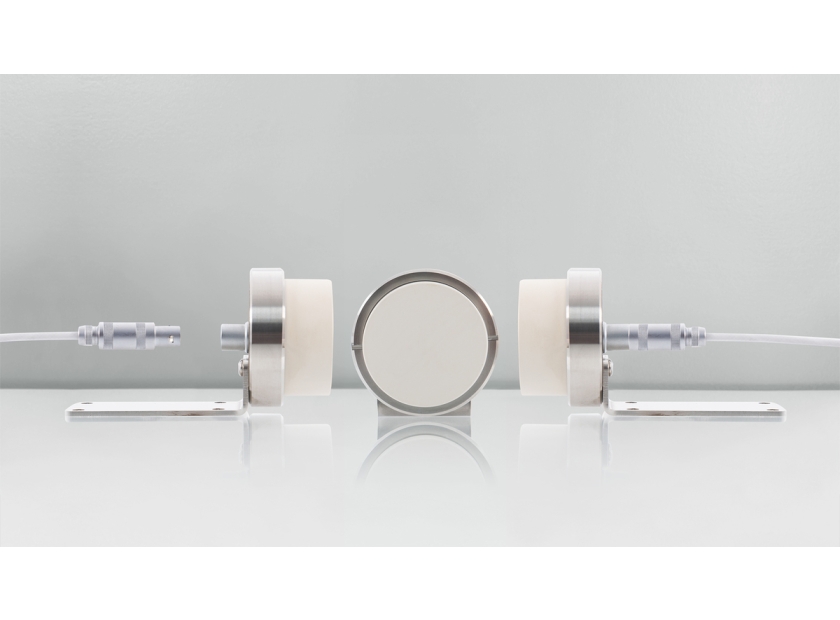

The wenglor LRL ring light is equipped with LEDs arranged in a circle that ensure uniform illumination intensity across the entire test object. With two sizes and three light colors, it is suitable for a wide range of applications and camera requirements in industrial image processing.

-

Posted: December 19, 2023Categories: WenglorRead More

Wenglor - Accurate Angle Measurement in Press Brakes

Integrated Directly into the Software of Standard Control System Manufacturers: MLSL1xxS50 for Accurate Angle Measurement in Press Brakes

Precisely bent sheets are required in a wide range of applications, for example in the automotive industry and shipbuilding.

-

Posted: April 02, 2023Categories: WenglorRead More

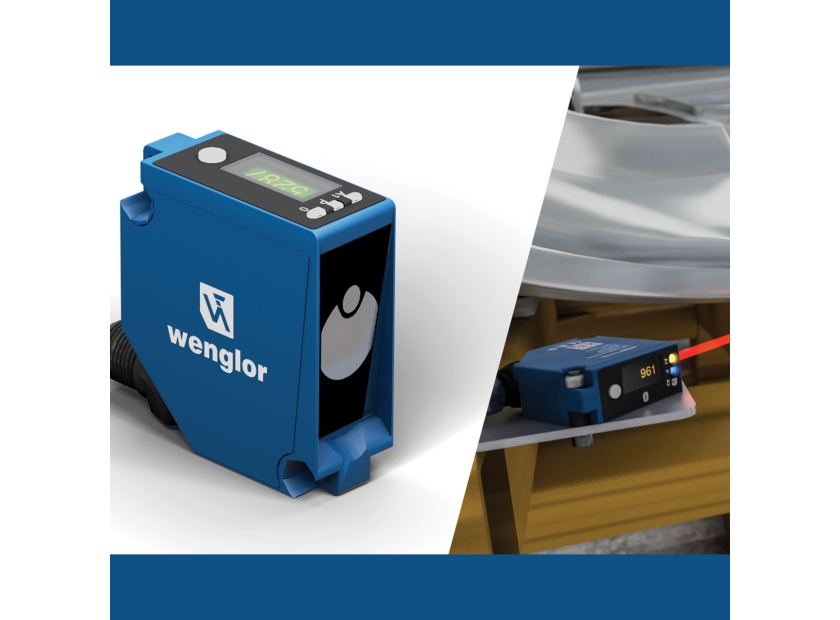

Precision, Performance and Usability in One

wenglor group Presents New Laser Distance Sensors TriangulationThis is CMOS power reimagined: The innovative triangulation laser distance sensors

from the P3 series provide precise measurement results at distances of up to 1,000 mm – accurate to a few microns. It’s not just the high accuracy that’s world-class, but also the intuitive operation concept, the high-quality aluminum housing and the built-in TripleA technology that gives the P3 series the status of gamechanger for triangulation sensors in industrial automation. A look inside the extensive 32 sensor series reveals why. -

Read More

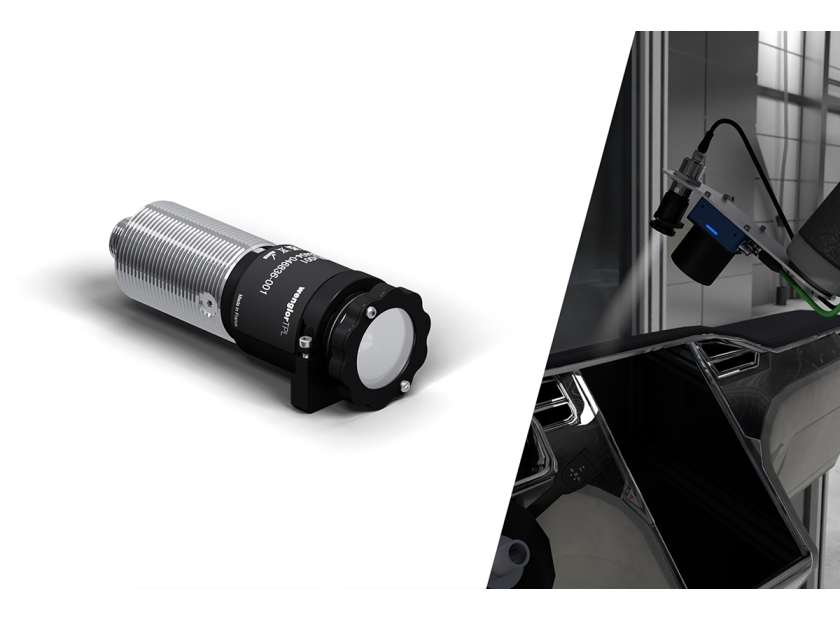

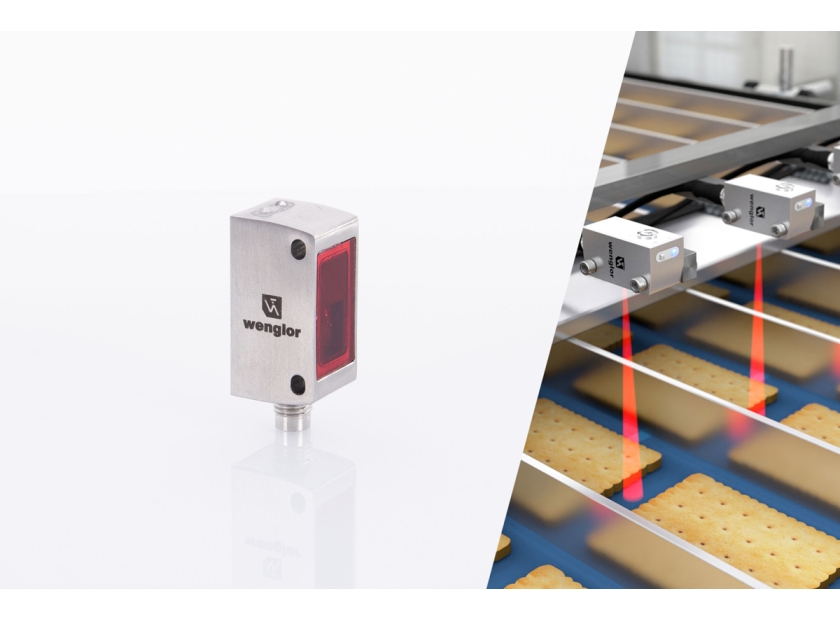

Specialists in harsh and demanding industrial environments: Type 2K photoelectronic sensors are the latest additions to the PNG//smart product series. Thanks to their robust stainless steel 316L housing with IP69K protection, they can withstand intensive high-pressure cleaning up to 100 bar at temperatures up to 80 °C, aggressive cleaning agents, coolants and lubricants, as well as mechanical influences and corrosion.

-

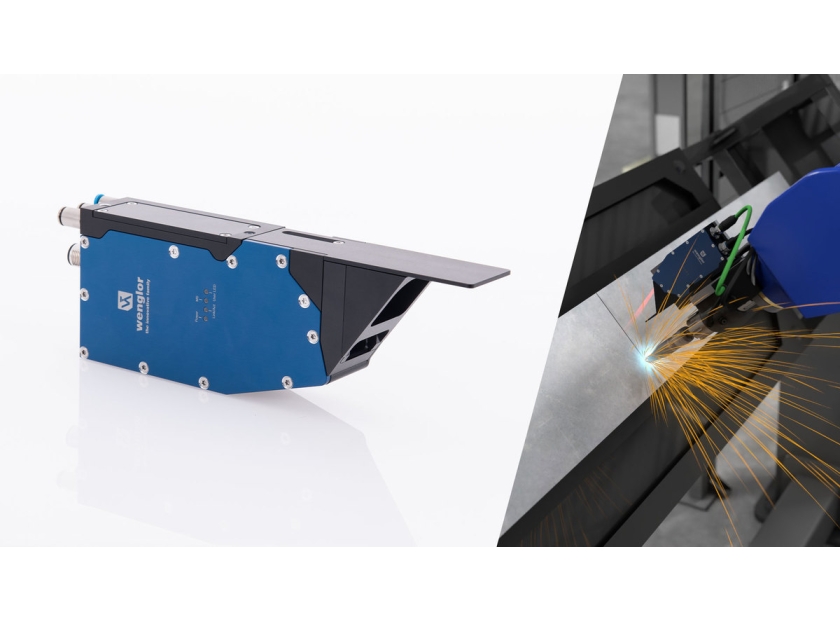

Posted: December 02, 2022Categories: WenglorRead More

Automated weld seam tracking in robot welding cells is a complex task in a harsh industrial environment. The micrometer-accurate detection of the guide point with different types of joint by 2D/3D profile sensors is one of the most effective solutions for this challenge. In combination with wenglor’s uniVision software, the new weCat3D MLZL 2D/3D tracker sensor not only combines the necessary precision and profile quality, but also offers convenient installation, integration, robustness and user-friendliness.

-

Posted: August 15, 2022Categories: SensorsRead More

Automated weld seam tracking in robot welding cells is a complex task in a harsh industrial environment. The micrometer-accurate detection of the guide point with different types of joint by 2D/3D profile sensors is one of the most effective solutions for this challenge. In combination with wenglor’s uniVision software, the new weCat3D MLZL 2D/3D profile sensor from Treotham not only combines the necessary precision and profile quality, but also offers convenient installation, integration, robustness and user-friendliness.

-

Posted: July 18, 2022Categories: SensorsRead More

The Wenglor INTT inductive sensors for extreme temperature ranges from Treotham detect metallic objects contactlessly at ambient temperatures of up to 250 °C. The new INTT series has two new features that make it even more flexible and robust. For dynamic applications in hot areas, system builders can now choose from flexible cables and simple push/pull connectors. The plug-in sensor heads are therefore easy to replace. The analysis module is also located directly in the M12 sensor plug. This innovative feature offers great added value for users who design or operate drying ovens for paint or surface coatings, for example.