welding robots

-

Posted: August 15, 2022Categories: SensorsRead More

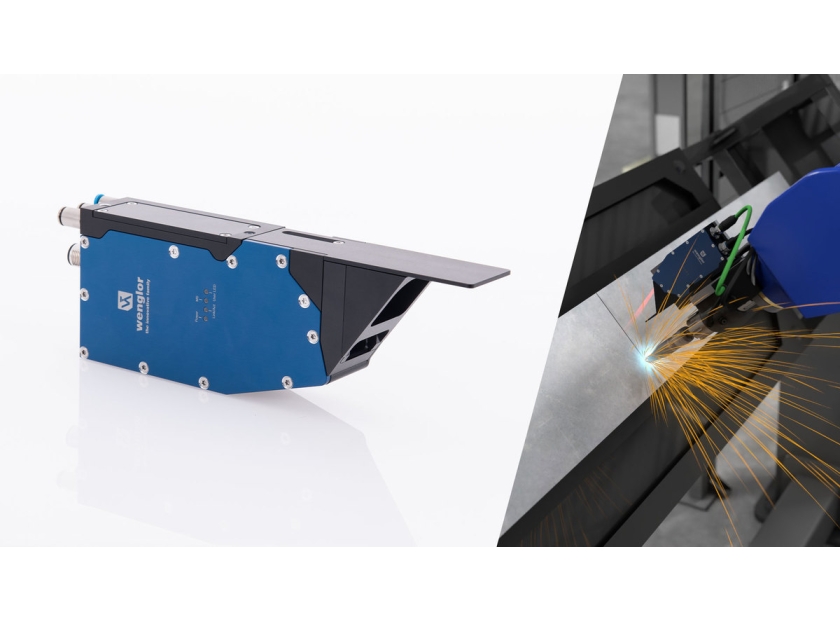

Automated weld seam tracking in robot welding cells is a complex task in a harsh industrial environment. The micrometer-accurate detection of the guide point with different types of joint by 2D/3D profile sensors is one of the most effective solutions for this challenge. In combination with wenglor’s uniVision software, the new weCat3D MLZL 2D/3D profile sensor from Treotham not only combines the necessary precision and profile quality, but also offers convenient installation, integration, robustness and user-friendliness.

Categories

- Gearboxes (2)

- PMA Cobot kits (1)

- Safety. (2)

- Safety (2)

- PMA Cable Protection Robotics (1)

- PMA cable protection (2)

- Cable Protection Robotics (0)

- Connectors (4)

- Robot conduits (0)

- Gear boxes (1)

- Flexible Cables (4)

- ILME (2)

- ILME (1)

- Treotham Automation (1)

- Gripper (0)

- Safety (10)

- Actuator (1)

- Lead Screw Nuts (0)

- Hygienic (4)

- Robot Cables (1)

- Wenglor (13)

- igus (80)

- Wieland (1)

- Wieland (0)

Recent Posts

Archive

Tags

igus

wenglor

euchner

bearings

energy chain

ilme

connectors

drylin

igubal

lapp

wittenstein

iglidur

automation

cables

chainflex

bearing

hygienic

food processing

igus energy chain

food industry

ready to connect

sensor

cks2

stainless steel

safety

robots

igus rebel

energy chains

ethercat

robust

sensors

robotics

thomson

robot

linear units

actuator

emc

prm

igludur

treotham

inductive sensors

enclosures

locking

e-chain

prt slewing ring

cable glands

gear box

lubrication-free

cleanrooms

compact