energy chain

-

Posted: August 20, 2024Read More

Bikes instead of cars: for the mobility transition to work, cities need more parking facilities without encroaching too much impact on the cityscape. For this purpose, the Japanese manufacturer Giken has built a garage called Eco Cycle,

-

Posted: May 15, 2023Read More

Maximum safety in battery production: first certified energy chain for the dry cleanroom

Test passed with the best possible result: E6.29 from igus receives innovative dry cleanroom certificate from Fraunhofer IPA for ISO Class 4

Whenever the highest hygiene standards are required, igus scores high with lubrication-free and abrasion-resistant plastic components for movement. In particular, battery production for tomorrow's mobility requires special environmental conditions, which are achieved through the combination of dry rooms and cleanrooms.

-

Posted: February 11, 2023Categories: igusRead More

Roller chain links reduce drive energy for the E4.1 energy chain series by 37%

Good news for users of the igus E4.1 energy chain series: newly developed roller chain links reduce required drive power by 37%. This allows customers to reduce their electricity costs in times of sharply rising energy prices.

-

igus advances the circular economy with the world’s first e-chain made entirely of recycled material

Posted: August 15, 2022Categories: Energy ChainsRead MoreCradle-to-cradle: This is the principle of the circular economy, which is abased on nature. The aim: to return consumer goods to the biological or technical cycle in order to conserve valuable resources and raw materials. The motion plastics specialist igus is also pursuing this goal and has now developed the world’s first energy chain made from recycled material on the basis of its own “chainge” e-chain recycling program.

-

Posted: March 15, 2022Categories: Energy ChainsRead More

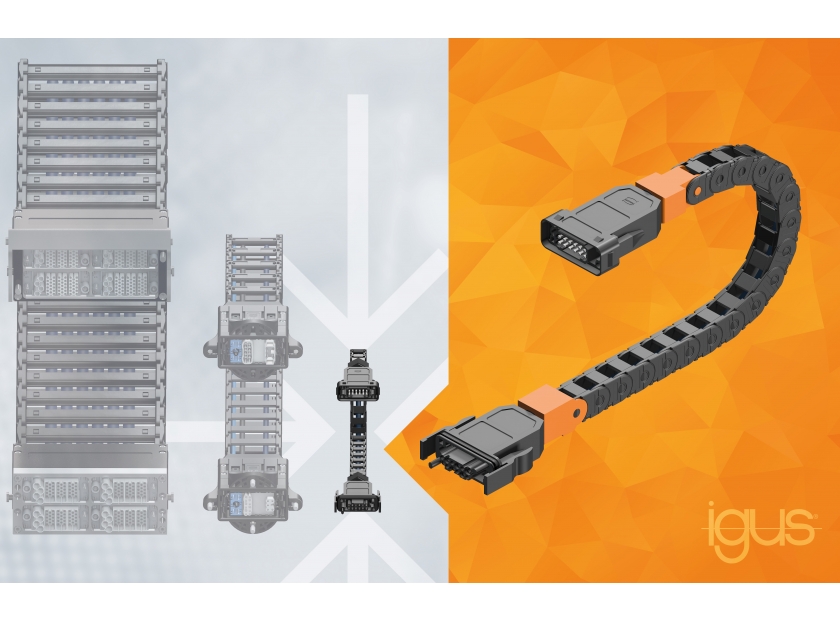

The plug-in igus energy chain system readychain speed from Treotham connects harnessed e-chain systems in seconds and without the use of tools. This helps reduce both throughput times in assembly and machine downtimes, and also brings planned maintenance work to a minimum. The ready-to-connect e-chain system thus saves 80% installation time. With the new readychain micro-speed, this is now also possible for very small applications and in particularly tight installation spaces.