thomson

-

Read More

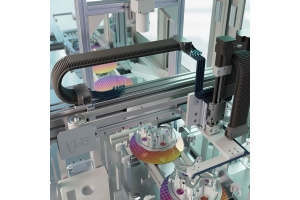

When determining if an application calls for a lead or ball screw, your decision should be guided through evaluating the inherent advantages and disadvantages of each. This evaluation process can have a significant impact on the performance and economic benefits of linear motion projects. The first step comes from understanding how they differ. Both ball and lead screws use threaded rods to convert from rotary to linear motion. Ball screws, as the name would imply, use recirculating ball bearings to minimize friction. Lead screws, by contrast, rely on a low coefficient of friction from sliding surfaces.

Categories

- Gearboxes (2)

- PMA Cobot kits (1)

- Safety. (2)

- Safety (2)

- PMA Cable Protection Robotics (1)

- PMA cable protection (2)

- Cable Protection Robotics (0)

- Connectors (4)

- Robot conduits (0)

- Gear boxes (1)

- Flexible Cables (4)

- ILME (2)

- ILME (1)

- Treotham Automation (1)

- Gripper (0)

- Safety (10)

- Actuator (1)

- Lead Screw Nuts (0)

- Hygienic (4)

- Robot Cables (1)

- Wenglor (13)

- igus (80)

- Wieland (1)

- Wieland (0)

Recent Posts

Archive

Tags

igus

wenglor

euchner

bearings

energy chain

ilme

connectors

drylin

igubal

lapp

wittenstein

iglidur

automation

cables

chainflex

bearing

hygienic

food processing

igus energy chain

food industry

ready to connect

sensor

cks2

stainless steel

safety

robots

igus rebel

energy chains

ethercat

robust

sensors

robotics

thomson

robot

linear units

actuator

emc

prm

igludur

treotham

inductive sensors

enclosures

locking

e-chain

prt slewing ring

cable glands

gear box

lubrication-free

cleanrooms

compact