Space-saving, abrasion-resistant

Space-saving, abrasion-resistant and dissipative: compact e-skin soft ESD for cleanrooms

Dissipative energy chain from igus with self-supporting function makes space-consuming shielding superfluous

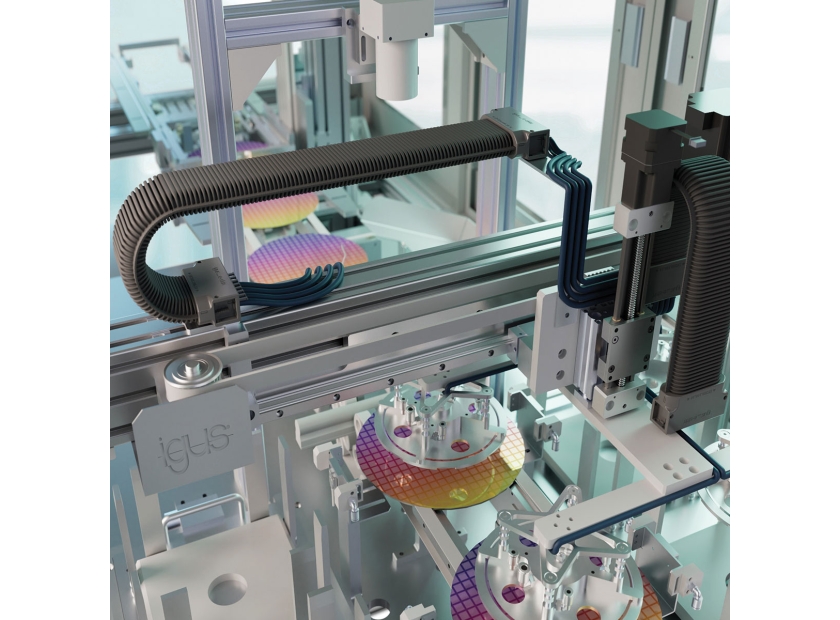

The demand for electric cars and the use of AI are growing, so that more and more lithium-ion batteries and microchips are required. As these technologies have to deliver performance that continues to increase, they are also becoming more sensitive and place high demands on production environments. With the e-skin soft ESD, igus is now launching a new energy chain for cleanrooms that is both abrasion-resistant and dissipative. It is a game changer for design engineers as it allows for significantly more flexibility and saves space in energy supply systems.

Tiny electrostatic discharges (ESD) are invisible to the eye, but can damage sensitive products in semiconductor and electronics production. It is therefore important that all machine components used in the vicinity of these products have ESD protection. However, this is not a matter of course when guiding power and data cables as they are generally not dissipative. "Many design engineers realise special kinds of shielding, but this wastes valuable space in cleanrooms," says Kira Weller, Product Manager for e-chains and Cleanroom Expert at igus. An equally impractical alternative is to keep a large distance from the product, which can also lead to space problems. To solve this dilemma, igus has developed a new version of the cleanroom-compatible e-skin soft energy chain: the e-skin soft ESD, a compact e-chain that is both abrasion-resistant and dissipative thanks to additives in the material. Electrostatic charges can be dissipated via the mounting brackets, similar to a lightning conductor. Says Weller: "The new energy chain is a game changer for design engineers as it can be used close to the product without additional shielding."

Space-saving e-chain allows for tight bend radii

The e-skin soft ESD has a compact design and requires very little installation space. It consists of an upper and a lower shell, which form a closed pipe housing that securely encloses pipes, cables or media guides. It is made from our own high-performance plastic, which allows for tight bend radii of 55mm. The inner height varies between 20mm, 24mm, 28mm and 40mm depending on the version, the inner width between 33mm, 48mm, 68mm and 85mm. Another thing that makes it special: thanks to its oval geometry and defined stiffness, the e-skin soft ESD can also realise unsupported lengths, unlike conventional corrugated hoses. This makes a guide superfluous. In addition, the energy chain is particularly durable and achieves a service life of more than 20 million double strokes.

On the way to the highest level of cleanliness, ISO Class 1

The e-skin soft ESD fulfils the strictest cleanroom requirements. "The high-performance plastic is extremely abrasion-resistant, so that no particles are produced during operation, even during fast movements," emphasises Weller. Particles from the cables cannot escape either as the upper and lower shells can be joined together to form a closed pipe using the zip principle. "This guarantees both cleanroom suitability and fast filling and maintenance of the cables," says Kira Weller. The new energy chain has already passed tests in the in-house cleanroom laboratory in Cologne, which was realised together with the Fraunhofer Institute for Manufacturing Engineering and Automation (IPA) with very good results. The official certification will come into effect in the coming weeks.