Practical upgrade for hot areas: System builders can keep a cool head

Practical upgrade for hot areas: System builders can keep a cool head

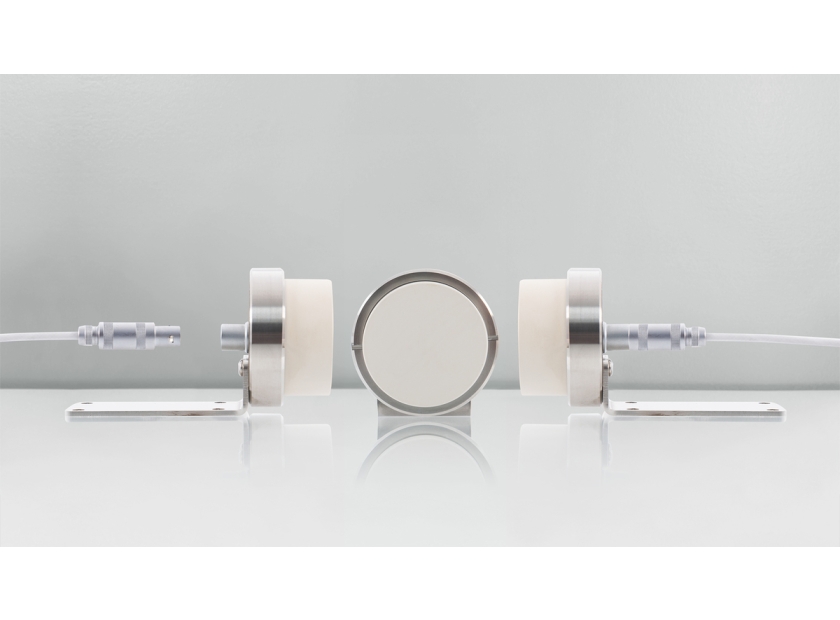

The Wenglor INTT inductive sensors for extreme temperature ranges from Treotham detect metallic objects contactlessly at ambient temperatures of up to 250 °C. The new INTT series has two new features that make it even more flexible and robust. For dynamic applications in hot areas, system builders can now choose from flexible cables and simple push/pull connectors. The plug-in sensor heads are therefore easy to replace. The analysis module is also located directly in the M12 sensor plug. This innovative feature offers great added value for users who design or operate drying ovens for paint or surface coatings, for example.

INTT Inductive Sensors for Extreme Temperature Ranges have a long service life of up to five years. If the sensors need to be replaced due to mechanical damage, the new series can be replaced in just one simple movement, even at high heat. The exchangeable sensor heads are connected to the system via a plug-in cable: “Even with fire-resistant gloves, the flexible cable can be very easily disconnected from the sensor thanks to the push/pull plug connection,” explains Wenglor Product Manager Dr. Sascha Reinhardt. “The advantage for users is obvious: Hot systems such as drying ovens do not need to be switched off for sensor replacement – replacement can now take place during operation with appropriate protective equipment.”

Flexible cables for dynamic applications

Another advantage is the expansion of the cable range, which now also includes an option for dynamic applications. Despite the high temperatures of up to 250 °C, the new cables are flexible and therefore ideal for dynamic applications on lifting platforms or elevator systems with skid beams. “The new cables also have a service life that is ten times longer than their predecessors in dynamic applications. This makes them extremely reliable and durable,” Dr. Reinhardt continues. The analysis module of the sensors is not integrated in an external housing, but directly in the plug with its small and compact design. This saves additional installation work and therefore costs. “This makes the new INTT series not only more flexible in terms of its possible applications, but also easier to maintain and handle,” says Dr. Reinhardt. “At the same time, it offers all performance values of the established INTT series.”

These include the long service life of over five years, the extensive temperature range between –10 °C and +250 °C and the large switching distances between 15 mm and 40 mm. The PWIS-free INTT series from Treotham can be parameterized via an IO-Link interface. Thanks to the integrated weproTec technology, several sensors can be installed directly next to each other in the tightest of spaces without interfering with each other.

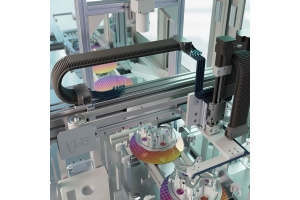

The sensors are used in particular in drying ovens in the automotive industry for precise positioning of skid beams. Inductive sensors are also suitable for extrusion of aluminum profiles, for the detection of goods carriers in the steel industry or for the detection of baking trays in large bakeries.

The Highlights at a Glance

- Temperature range –10 °C to +250 °C

- Service life of more than 5 years

- Switching distances from 15 mm to 40 mm

- M12 sensor plug with integrated analysis module

- Flexible cable for dynamic applications

- IO-Link 1.1

- Interchangeable sensor head

- PWIS-free