Solar cables for maximum solar power

Solar cables for maximum solar power available from Treotham Automation

With the EPIC® SOLAR 4 GEN2 patch, LAPP is offering customised patch cables specifically for the solar industry for the first time - in individual lengths and to the highest quality standards.

In the solar and photovoltaic sectors in particular, patch cables are increasingly needed to guarantee the efficiency and reliability of solar systems. They help to simplify system installation and make maintenance easier. For example, installers need the patch cables to connect solar modules together and enable series or parallel connection so that the direct current they generate (up to 1,500 volts) can be efficiently collected and forwarded. For use in households and power grids, the direct current (DC) must then be converted into alternating current (AC) using inverters. Here too, patches reliably connect the solar modules to the inverters.

Highest quality and reliability in data transmission

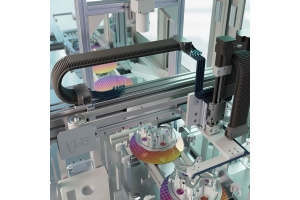

LAPP offers customers in this area a particularly efficient and time-saving solution from a single source: The prefabricated EPIC® SOLAR 4 GEN2 patch assembly consisting of the TÜV SÜD-tested EPIC® SOLAR 4 GEN2 connector and the ÖLFLEX® SOLAR H1 BUR solar cable guarantees users the highest quality standards and traceability. The automated crimping with pressing force and torque monitoring when tightening the screw connection also promises maximum reliability and a vibration-proof connection thanks to maximum contact reliability between contact and cable.

The automated assemblies offer a major advantage over conventional solutions, as previously assemblies often had to be created on site at the solar park, cables had to be cut to length and crimped and the connectors had to be assembled by hand. LAPP is now able to fulfil this entire process in-house at competitive prices and with multi-stage quality assurance. Faulty connections are thus ruled out. The machines for this production step were purchased specifically for this purpose.