The safe key for automated intralogistics processes

The safe key for automated intralogistics processes

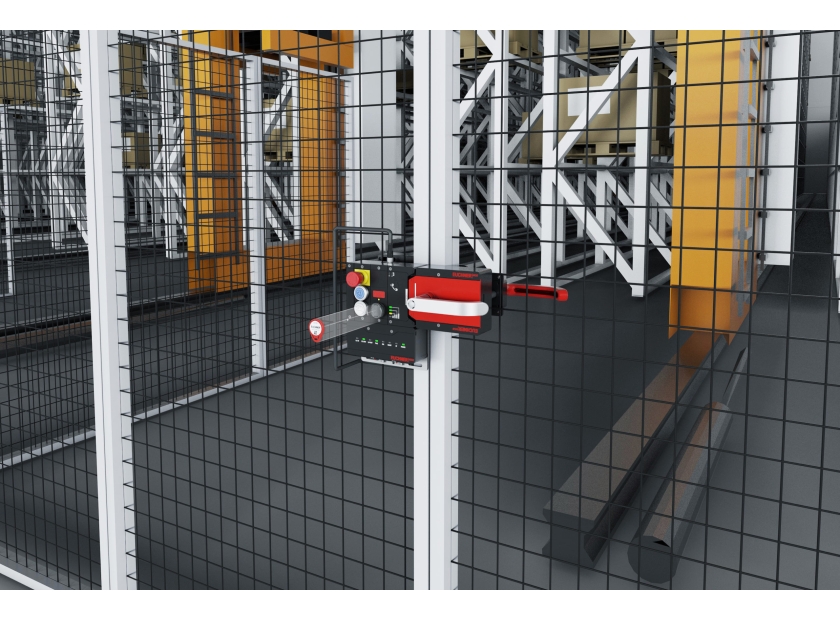

Consider a highly automated logistics center with fenced-in robots and storage and retrieval machines, conveyor systems and pallets as far as the eye can see. How can companies keep their employees safe from accidents inside the warehouse while maintaining a smooth material flow? Euchner promises that its new CKS2 key system will greatly simplify handling for safe starting or stopping of dangerous machine movements. Intralogistics system integrators benefit from a highly flexible, customizable and scalable system that does away with complicated key exchange boxes. This safe RFID solution is a great complement to the MGB2 Modular safety door system.

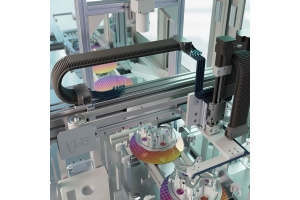

Whether for consumer goods, e-commerce, beverages, fresh foods or pharmaceutical products – automating warehouse and intralogistics processes is becoming more important all the time. Automation simplifies and speeds up processes, enhances efficiency and optimizes supply chains in diverse sectors. Warehouse employees organize product inflows and outflows using modern storage and retrieval machines, robots and conveyor systems. Besides trouble-free operation, safety takes top priority – the tall storage rack systems are highly automated, and employees must be kept out of the danger zone. However, they must still be able to access the interior safely if an unplanned standstill should occur. This calls for reliable safety engineering capable of safe installation lockout and rapid restarting.

Highly flexible safety door system: modular and customizable

The MGB2 Modular has proven its worth over many years in sectors as diverse as the automotive and logistics industries, where it secures safety doors and fences on machines and installations during dangerous machine movements. This modular safety door system from Euchner consists of a locking module; integrated submodules with controls and indicators for pushbuttons, selector switches, key-operated rotary switches or emergency stop buttons; any required expansion modules and various bus modules for connecting to PROFINET/PROFIsafe or EtherCAT P/FSoE. It works especially well when combined with the CKS2 safe key system, enabling many new applications.

One key, many functions

The new CKS2 key system can be used for machine and installation lockout and starting, for assigning authorization to select an operating mode, or as a trapped key system. The system guarantees maximum safety thanks to its highly coded RFID keys. The CKS2 can be used in an installation either individually as a compact system with integrated evaluation electronics or separately as a submodule in the MGB2 Modular door locking system. This opens up a host of new applications to users – as well as numerous combination options.

The CKS2 system is readily adaptable to individual requirements. Depending on the specific application, the key can be left in place or removed during automatic operation. When the system is used for locking out, the installation cannot be started without the key, for example. In other words, the key stays in the key adapter station during operation. The key is removed to stop the installation. Only then will a dangerous zone become accessible.

When the CKS2 is used with the additional access restriction function, operators must insert the key before entering the installation. One example is the application in an automated logistics center: The MGB2 Modular’s safety door system secures the long transport aisles. The CKS2 is integrated as a submodule in an MGB2 locking module, along with a pushbutton for starting or stopping the machine. If a product package falls off a rack in a transport aisle, the person responsible can stop the installation behind the safety fence by inserting the key into the key adapter and pressing the pushbutton to request access. This pushbutton is an integral part of the MGB2 door locking system and sends a signal to the connected control system, which stops the machine in a safe position. Only then does the employee withdraw the key and open the door to return the package to the right place. The installation can be restarted once the person has left the danger zone. This person then inserts the key into the key adapter from the outside and presses the pushbutton to activate door locking.

“Intralogistics customers also use the CKS2 as a trapped key system,” says Xabier Antolin, product manager at Euchner. The RFID keys are simply taught-in at several key adapters for this purpose. The same key can then be used in another key adapter of a machine or robot in the interior to perform manual work there, for example. When the user has finished their work, they remove the key again, leave the interior, re-insert the key into the MGB2 key adapter on the outside and start the installation in the interior by acknowledging with the pushbutton.

High coding level, maximum flexibility

The CKS2 presents many advantages over conventional systems: its highly coded keys enable many installations to be secured using the same system. “Protecting 30 transport aisles used to require highly complex systems, for example. We’re not limited with the CKS2, because it can be scaled as needed,” explains Antolin. Connecting the MGB2 module via bus systems enables all key adapters to be monitored in the overall control system.

Keys are easy to manage – the electronic principle of operation renders key exchange boxes and distribution stations obsolete and eliminates complicated configuration work. Another benefit is that applications are defined directly in the control system for maximum flexibility. “Convincing arguments in favor of the new system include safety and the time savings if a key should become lost,” adds Antolin. “It’s then simply a matter of teaching-in a new RFID transponder. The old key will no longer work, and nobody can copy it.”

In addition to the automotive industry, the target group for the new key system includes warehouse builders and providers of logistics systems and intralogistics solutions. This system is well suited to applications in the food and pharmaceutical industries because the switches can withstand even extremely cold temperatures. “The CKS2 is compatible with complete turnkey installations. Pairing it with the MGB2 forms a strong team that is the perfect choice to provide a wealth of attractive solutions for fully automated logistics systems with large warehouses and numerous aisles,” says product manager Antolin, who is currently holding discussions with various customers.