Page 7 - News

-

Posted: July 02, 2024Read More

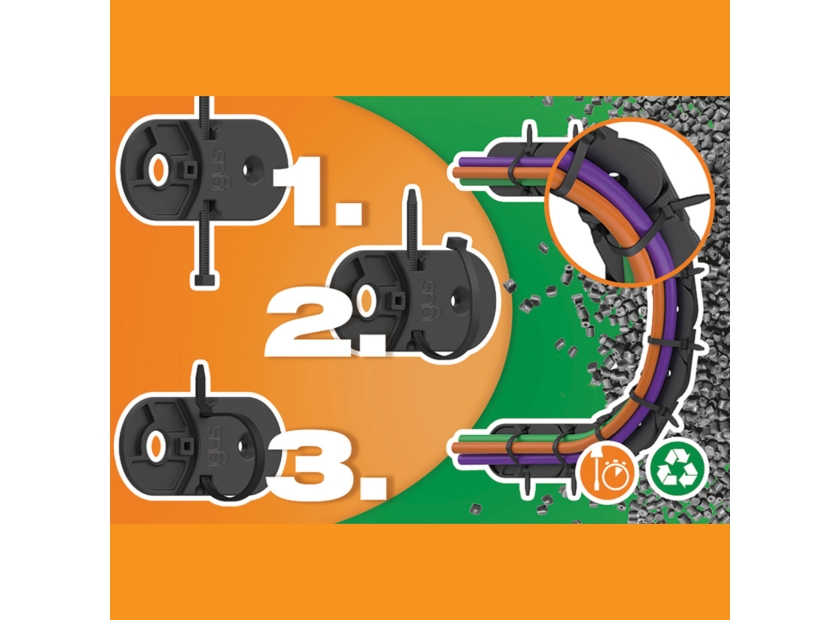

Things don't have to be expensive. This is true not only of groceries, but also of energy chains. The simplest products often not only cost the least, but also represent the best technology. igus has now developed the snapchain 2.0 especially for low-stress and flat cable packages.

-

Read More

The MGB2 Modular secures safety doors and fences on machines and installations during hazardous machine movements. A modular design is the secret behind the system’s adaptability to specific requirements.

-

Posted: June 25, 2024Read More

With the EPIC® SOLAR 4 GEN2 patch, LAPP is offering customised patch cables specifically for the solar industry for the first time - in individual lengths and to the highest quality standards.

In the solar and photovoltaic sectors in particular, patch cables are increasingly needed to guarantee the efficiency and reliability of solar systems.

-

Read More

Mobile robotic systems are being used in more and more work areas, from e-commerce warehouses to modern restaurants. However, widespread use is often unaffordable for small and medium-sized companies due to the high prices. igus wants to change this with new low-cost robotics offerings and is presenting a series of low-cost mobile plastic robots.

-

Read More

The metal processing industry has relied on industrial safety engineering from Euchner for decades. Highlights at this year’s EMO include the latest communicating safety guard locking devices, the new CTS compact guard locking device, and the CTA safety switch for harsh environments. Euchner will also be showcasing its versatile new CKS2 key system for machines and installations. The proven MGB2 Modular for safety doors is now available for EtherCAT/FSoE as well.

-

Read More

The CKS2 from Euchner is a new, safe key system that is simple to integrate into the overall control system and suitable for a wealth of applications.

-

Posted: May 14, 2024Read More

snapchain 2.0: small, compact and cost-effective energy supply system

The new igus energy chain made entirely of recyclate can be installed in seconds and guides cables reliably available from Treotham.

-

Read More

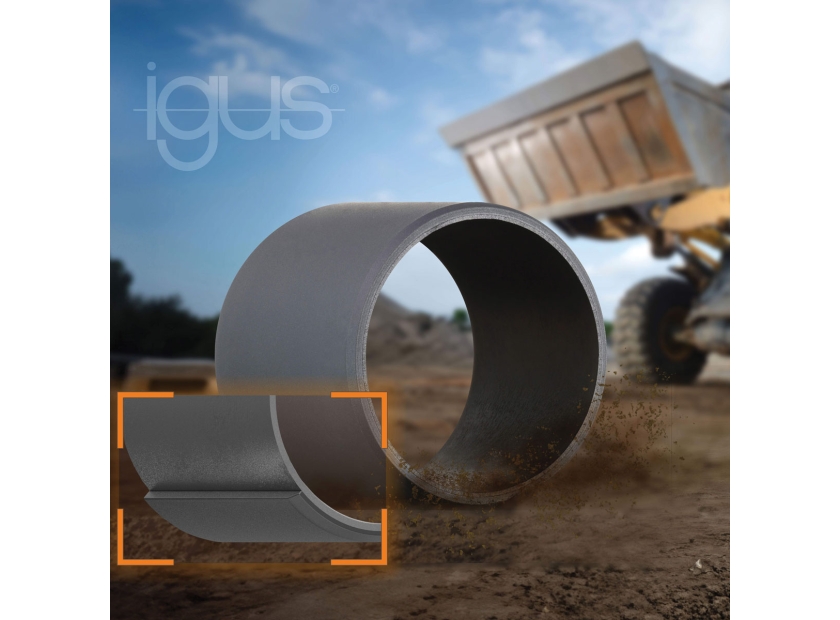

igus develops a two-component injection-moulded plain bearing for high mechanical loads

-

Read More

Play before you pay: Virtually configure the ReBeL in the iguversum, the new igus digital tool and control it remotely – just one of many options that will make it even easier for igus robotics users to get started with Low Cost Automation in the future.