LAPP presents a sustainable Cable

LAPP presents a sustainable cable with a PVC sheath

Sustainability from the DNA to the portfolio

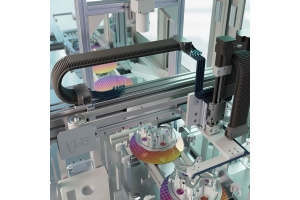

Acting sustainably is deeply embedded in the LAPP DNA. This is increasingly reflected in the product portfolio: With the ETHERLINE® FD P Cat. 5e the LAPP portfolio already includes a cable with a sheath made from a bio-based TPU jacket material. Now, with the ÖLFLEX® CLASSIC FD 810, this will be followed by the prototype of a cable with a durable PVC sheath.

In order to leave behind a planet worth living for the next generation, the LAPP focus is on sustainable and environmentally friendly management and responsible handling of all natural resources. For this reason, the family company, a leading provider of integrated solutions in the field of cable and connection technology, has been working on how to reduce the carbon footprint of its own products for some time now. One solution is the use of bio-based plastics as sheath materials. At Hannover Fair 2023, LAPP already launched a sustainable variant of the ETHERLINE® FD P Cat. 5e. Its plastic sheath (TPU) consists of a maize-based biopolymer.

Technology driver LAPP is working on more sustainable solutions.

“The sustainable ETHERLINE® variant attracted a great deal of interest "This is why we have gone one step further with our innovation processes and are working on more sustainable cable variants." The result of the technology driver is a more sustainable variant of the ÖLFLEX® CLASSIC FD 810.

Until now, the sheath had been made of polyvinylchloride, PVC for short, the most important plastic in the cable industry. The challenge is that previously, it was not technically possible to produce PVC based entirely on bio-based raw materials. A partially bio-based sheath made of PVC compound, with a bio-based content of 42% according to ASTM6866. is therefore a start.

“The ÖLFLEX® CLASSIC FD 810 is a highly versatile cable that is also designed for use in drag chains. It can additionally be used to test the cable chain properties of the material. This means it offers a wide range of tests for carrying out material inspections for certifications,” says Alexander Terpe of the prototype. “For us at LAPP, the ÖLFLEX® CLASSIC FD 810 is therefore the ideal starting point for further projects aimed at sustainability and reducing our carbon footprint.”

Customers reduce their own CO2 footprint

The advantage for Treotham customers is that if they purchase a sustainable variant of the cables, they will thus reduce their own carbon footprint – without having to pay for any losses in quality or product properties. Properties for durability, flexibility and mechanical properties, as well as hydrolysis, chemical and UV-resistance, are no different from those of their sister cables made from conventional PVC or TPU. Yet the connection specialist’s innovative approach does not end here either: “The aim for LAPP is to bring more and more sustainable products onto the market that can be used to save on fossil resources and CO2 emissions. Our goal is to offer our customers more sustainable solutions in the future," says Alexander Terpe. LAPP is pioneering this deliberately and acting early before legislation or other political regulations come into force."