So very clean: new igus slewing ring bearing for food contact

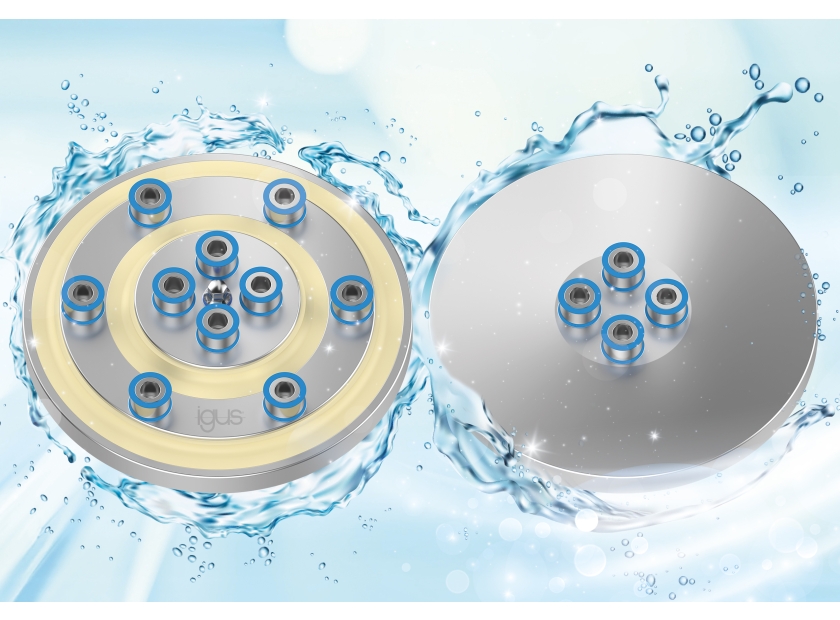

The hygienically designed slewing ring bearing from the iglidur PRT series allows cleaning without disassembly

Hygienically designed slewing ring bearings have been scarce on the market. Manufacturers of special machines for hygiene-sensitive areas therefore often have to design additional covers. However, igus is now changing all that - with a hygienically designed iglidur PRT slewing ring bearing that enables quick, residue-free cleaning during use. This slewing ring bearing can remain permanently installed in an application with food contact, saving the user the effort of developing a suitable cover.

Manufacturers of special machinery for hygiene areas in the food, medical and pharmaceutical industries are familiar with the problem: the market has hardly any hygienically designed slewing ring bearings for rotating components in such applications as a bottle filling plant. Classic models offer bacteria plenty of target areas, and usually cannot be cleaned thoroughly enough. Hence, additional development work for a hygienic cover is usually necessary, involving more time and money. "We want to offer a simpler solution, so we developed a hygienic version of our iglidur PRT slewing ring bearing," says Fabian Wieking, Product Manager PRT Slewing Ring Bearings at igus. "It is made of stainless steel and FDA-compliant plastics, and its design allows users to clean it without any residue left behind and without removing it from the machine. This eliminates the need for an additional cover."

New design allows easy cleaning during use

When constructing the new slewing ring bearing, igus engineers followed the guidelines of the European Hygienic Engineering and Design Group, an association of research institutes, public-health institutions, food processors and food production equipment suppliers. The primary goal was to give bacteria as few target areas as possible. The user will therefore find no 90-degree corners, weld seams or edges. All slewing ring bearing components are rounded. All surfaces also have a slope of at least three degrees so that water drains off completely. FDA-compliant seals are used wherever metal meets metal. This prevents dead spaces - in screw connections, for example. "These special design features allow clean-in-place processes," says Wieking. "No disassembly is necessary for cleaning. Users can simply rinse the bearing with cleaning agents, reliably removing all residue."

igus manufactures a new special-component slewing ring bearing upon request

The hygienic design version of the PRT slewing ring bearing is a market-ready study. "We see that the food and packaging industry is developing rapidly and that there is greater and greater demand for special machinery," says Wieking. "However, in most cases, manufacturers require special components. For that reason, we are offering them the possibility to have the new hygienically designed slewing ring bearing manufactured according to their individual requirements." Users also benefit from the usual advantages of igus products: the stainless steel rings move on sliding elements made of iglidur, a high-performance plastic into which solid lubricants are integrated. They allow low-friction dry operation, protecting the environment. The slewing ring bearings are delivered ready to install, and the self-lubrication effect keeps them working for years without maintenance.