Metaprint Automation

Metaprint automates the loading of printing machines with XXL linear robot from igus

Estonian aerosol packaging manufacturer increases production efficiency and reliability with a customised Low Cost Automation solution

Customised automation doesn't have to be expensive. Metaprint AS from Estonia, one of the largest manufacturers of aerosol packaging in Europe, demonstrates this. The company now uses an XXL linear robot from igus to load a printing machine. Compared to conventional systems, this Low Cost Automation solution reduces investment costs and is also easy to put into operation thanks to the plug & program function.

There are routine tasks that nobody likes to do - be it vacuuming at home or loading of machines in industry. While vacuum robots are increasingly being used in homes, the Estonian company Metaprint AS relies on an XXL linear robot from igus in production. "The robot's task is to load a printing machine with thin sheet metal blanks," says Development Engineer Kristofer Ott Sutt. "It noticeably reduces our employees' workload and has also helped increase efficiency in production." Metaprint AS was founded in 1891 and is now one of the leading manufacturers of aerosol packaging in Europe. The sprays are used for products such as pesticides in agriculture and baking release agents in the food industry.

"Without this solution, we probably wouldn't have been able to realise our automation plans"

The automation of printer loading proved to be much more complex for Metaprint than expected. The price was a particular headache. "I asked for a few quotes from Estonian mechanical engineers," Sutt recalls. "But they were well above our budget." The solution finally came in the form of the XXL linear robot from igus, which was originally developed for palletising applications. It costs up to 60% less than comparable solutions and is also easy to put into operation thanks to its plug & program function. "The low-cost system is ideal for small and medium-sized companies with a limited budget. Without this solution, we probably wouldn't have been able to realise our automation plans." It is also worth noting that this is not a standard solution. "Together with igus as a system supplier, we were able to realise a customised special solution within a few weeks for a reasonable price."

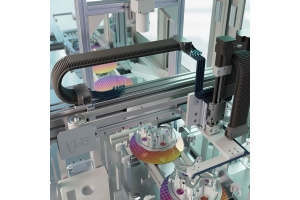

Robot places sheet metal blanks with an accuracy of +/-0.5mm

With a working area of 4,700 x 2,600 x 900mm, the igus linear robot in use is the largest of its kind in Estonia. It looks like a gigantic 3D printer. It consists of lubrication-free drylin linear units and energy chains from the E2i series, which ensure safe cable guidance on the robot. The latter are characterised by a long service life, particularly quiet operation and easy filling and assembly. One of the products used here is the E2i.15 energy chain, a particularly small, lightweight energy chain that is ideal for highly dynamic applications and the smallest installation spaces. A gripper with four vacuum suction cups picks up the sheet metal blanks from a pallet and places them on a table in the centre of the linear robot - with a repeatability of +/-0.5mm and a load capacity of up to 25kg. Two additional aluminium profiles are assembled on the sides of the table, on which another crossbeam with three suction pads moves. The grippers push the blanks into the printer's feed area - this automation eliminates the need for tedious manual positioning and feeding.

Video on the application: https://www.youtube.com/watch?v=Qo0kqB3gazE