drylin t

-

Posted: August 15, 2022Read More

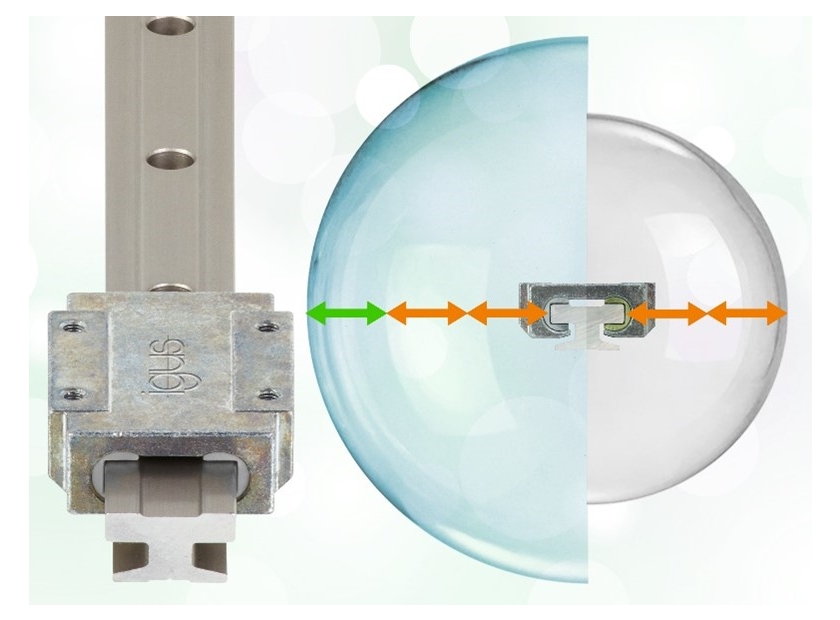

Whether in an industrial environment or in a coffee machine, in order to maximize the service life of a linear guide and to keep the required drive energy low, it is important to reduce friction and wear as much as possible. igus, a motion plastics specialist, has now achieved a breakthrough in tribological plastics: With iglidur E3, igus has developed a new sliding material that has a friction coefficient that is up to 40 percent better and thus opens up design flexibility in linear technology for users for the first time from the classic 2:1 Rule expanded to 3:1. The new iglidur E3 sliding material is available from Treotham.

Categories

- Gearboxes (2)

- PMA Cobot kits (1)

- Safety. (2)

- Safety (2)

- PMA Cable Protection Robotics (1)

- PMA cable protection (2)

- Cable Protection Robotics (0)

- Connectors (4)

- Robot conduits (0)

- Gear boxes (1)

- Flexible Cables (4)

- ILME (2)

- ILME (1)

- Treotham Automation (1)

- Gripper (0)

- Safety (10)

- Actuator (1)

- Lead Screw Nuts (0)

- Hygienic (4)

- Robot Cables (1)

- Wenglor (13)

- igus (80)

- Wieland (1)

- Wieland (0)

Recent Posts

Archive

Tags

igus

wenglor

euchner

bearings

energy chain

ilme

connectors

drylin

igubal

lapp

wittenstein

iglidur

automation

cables

chainflex

bearing

hygienic

food processing

igus energy chain

food industry

ready to connect

sensor

cks2

stainless steel

safety

robots

igus rebel

energy chains

ethercat

robust

sensors

robotics

thomson

robot

linear units

actuator

emc

prm

igludur

treotham

inductive sensors

enclosures

locking

e-chain

prt slewing ring

cable glands

gear box

lubrication-free

cleanrooms

compact