Page 3 - igus

-

Posted: September 18, 2022Categories: BearingsRead More

Whether mountain bikes for outdoor use, record-breaking light racing bikes or ultra-robust e-cargo bikes: Treotham presents new igus components made of high-performance plastic as an alternative to metal solutions for the bikes of the future – including light and lubricant-free polymer plain bearings for mountain bikes, wear-resistant gears for e-bike motors and robust rod ends for e-cargo bikes.

-

Posted: August 15, 2022Read More

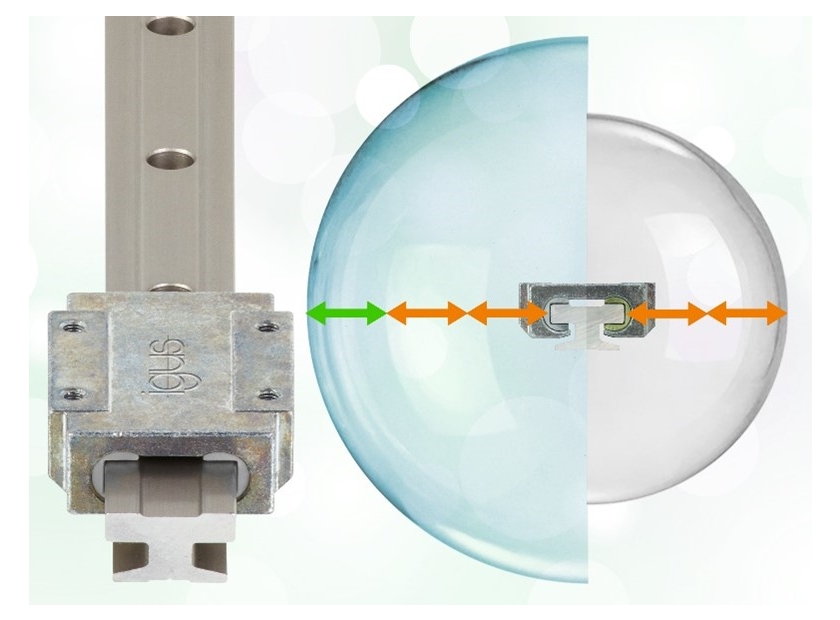

Whether in an industrial environment or in a coffee machine, in order to maximize the service life of a linear guide and to keep the required drive energy low, it is important to reduce friction and wear as much as possible. igus, a motion plastics specialist, has now achieved a breakthrough in tribological plastics: With iglidur E3, igus has developed a new sliding material that has a friction coefficient that is up to 40 percent better and thus opens up design flexibility in linear technology for users for the first time from the classic 2:1 Rule expanded to 3:1. The new iglidur E3 sliding material is available from Treotham.

-

igus advances the circular economy with the world’s first e-chain made entirely of recycled material

Posted: August 15, 2022Categories: Energy ChainsRead MoreCradle-to-cradle: This is the principle of the circular economy, which is abased on nature. The aim: to return consumer goods to the biological or technical cycle in order to conserve valuable resources and raw materials. The motion plastics specialist igus is also pursuing this goal and has now developed the world’s first energy chain made from recycled material on the basis of its own “chainge” e-chain recycling program.

-

Posted: July 18, 2022Categories: BearingsRead More

Treotham has expanded its wide range of igus iglidur round bars with four materials; among them two for the food sector: the heat-resistant material iglidur AC500 and the resilient material A250. The extremely hard-wearing material iglidur H3 and the particularly wear-resistant endurance material iglidur E complete the product range. This makes it possible to mill and turn lubrication-free and maintenance-free prototypes and special components for a wide variety of applications.

-

Posted: May 31, 2022Categories: BearingsRead More

Even tried and tested structures have potential for improvement. One example is the classic trapezoidal thread, which igus has refined. Thanks to a special geometric interaction between the lead screw nut, which requires no lubrication or maintenance, and the metal lead screw, dryspin technology promises a long service life, improved efficiencies, low wear and less movement noise.

-

Posted: May 02, 2022Categories: BearingsRead More

Articulated arm robots can travel over six metres, quadrupling their working space: the 7th axis is now compatible with all lightweight articulated arm robots worldwide thanks to a simple Plug & Play kit. So far, models from Universal Robots, Epson and the igus robolink series from Treotham have benefited from this increased mobility. Now Omron, Franka Emika, Doosan, Yuanda Robotics and many other lightweight robotics suppliers are joining the list.

-

Posted: May 02, 2022Categories: Energy ChainsRead More

It is light, compact, and made entirely of plastic: the new PRM (Polymer Rotation Module) rotary igus energy supply system from Treotham. Specifically for tight rotational movements in cables and hoses, igus has now developed a system consisting of a polymer energy chain and a low-friction plastic guide trough. Users can increase the service life of their machines and systems with buying costs up to 73% less than those of a comparable steel guide trough. The new e-chain system expands the igus range of complete sets that can be ordered directly from Treotham Automation.

-

Posted: April 28, 2022Categories: BearingsRead More

Many stroke patients worldwide suffer from hemiplegia (partial paralysis). Exoskeletons such as Harmony from Harmonic Bionics can help rebuild the nerve tracts in arms and shoulders. In order to quickly adapt the robot supported system to different body sizes in physiotherapy, the developers rely on lightweight, lubrication-free and maintenance-free plain bearing technology from igus.

-

Posted: April 11, 2022Categories: BearingsRead More

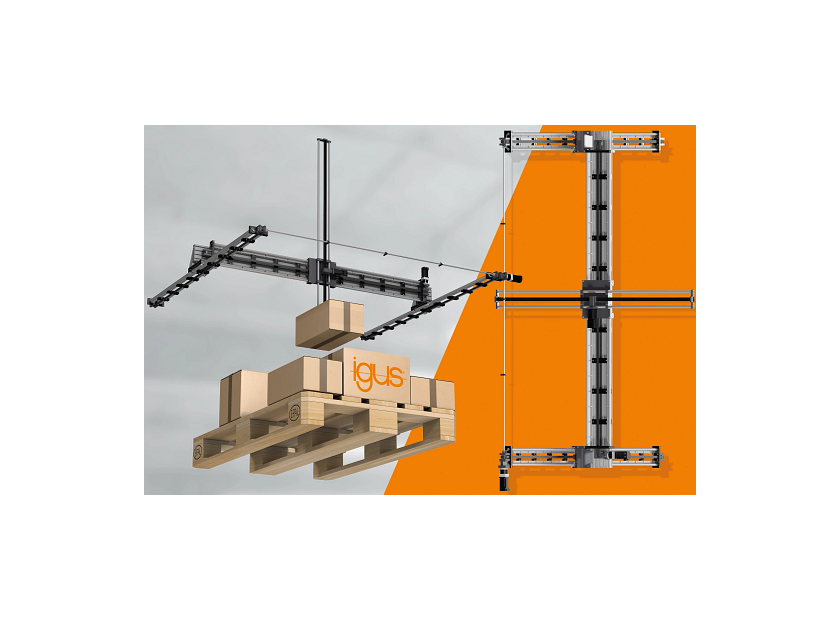

Treotham is expanding its broad Low Cost Automation range with a new drylin XXL room linear robot. The linear robot has an action radius of 2,000 x 2,000 x 1,500 millimetres and is particularly suitable for palletising applications of up to 10 kilograms. The robot is includes the control system, and is easy to set up and program yourself using the do-it-yourself principle – without the help of a system integrator.

-

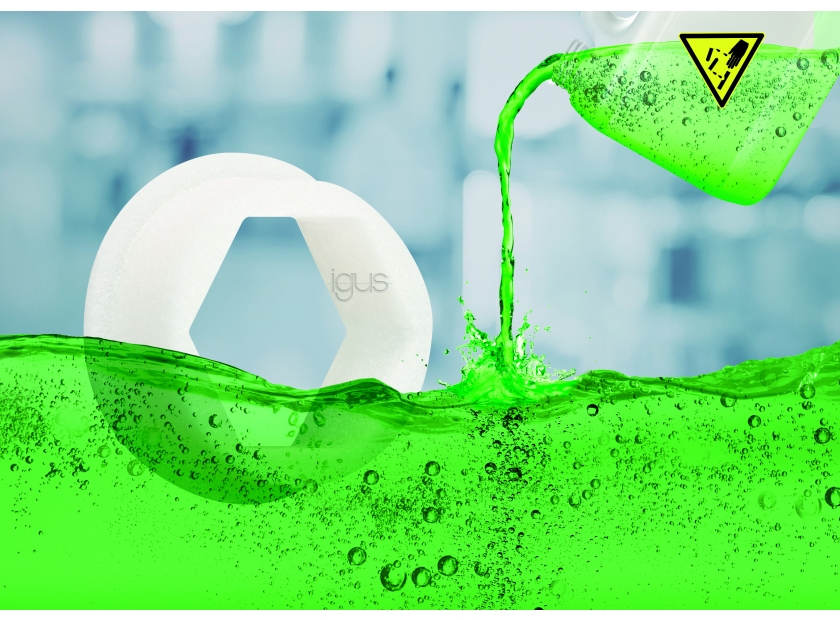

Posted: April 05, 2022Categories: BearingsRead More

igus is expanding the scope of its 3D printing service: Chemical-resistant, lubrication-free tribo-polymer components can be manufactured using selective laser sintering (SLS). This evolutionary step is made possible by a new printing material for laser sintering printers: iglidur I10 is resistant to acids, bases, alcohols as well as greases and is therefore suitable for use in electroplating and food processing plants. The 3D filaments are also available to purchase directly from Treotham if the customer wishes to print themselves.